ISO 26262 is an internationally recognized standard for ensuring the functional safety of automotive systems, particularly in road vehicles.

Safety Commander play a pivotal role in implementing ISO 26262 by overseeing safety-related assessments, validations, and compliance measures.

Safety Commander responsible for safeguarding the integrity and reliability of critical automotive components and systems, ensuring they meet stringent safety standards to enhance overall vehicle safety and mitigate potential risks

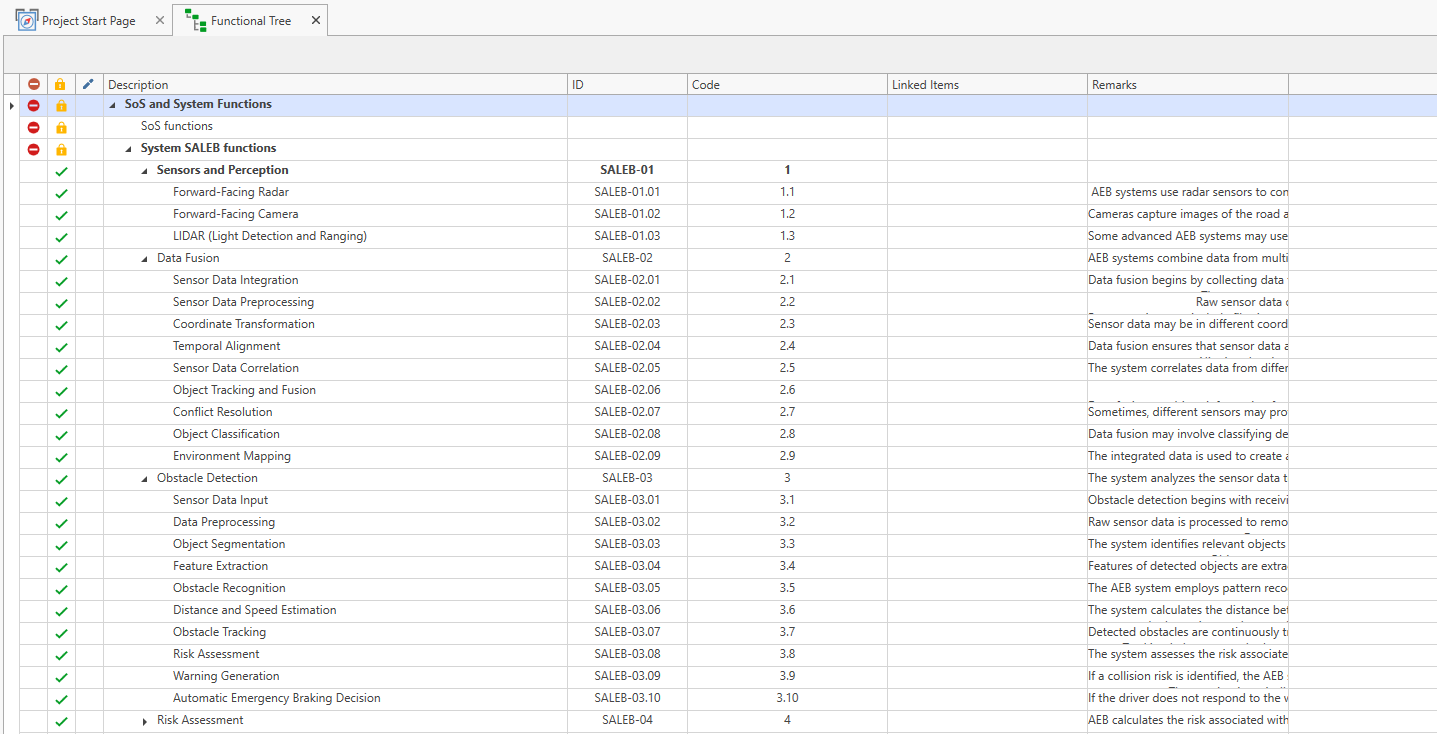

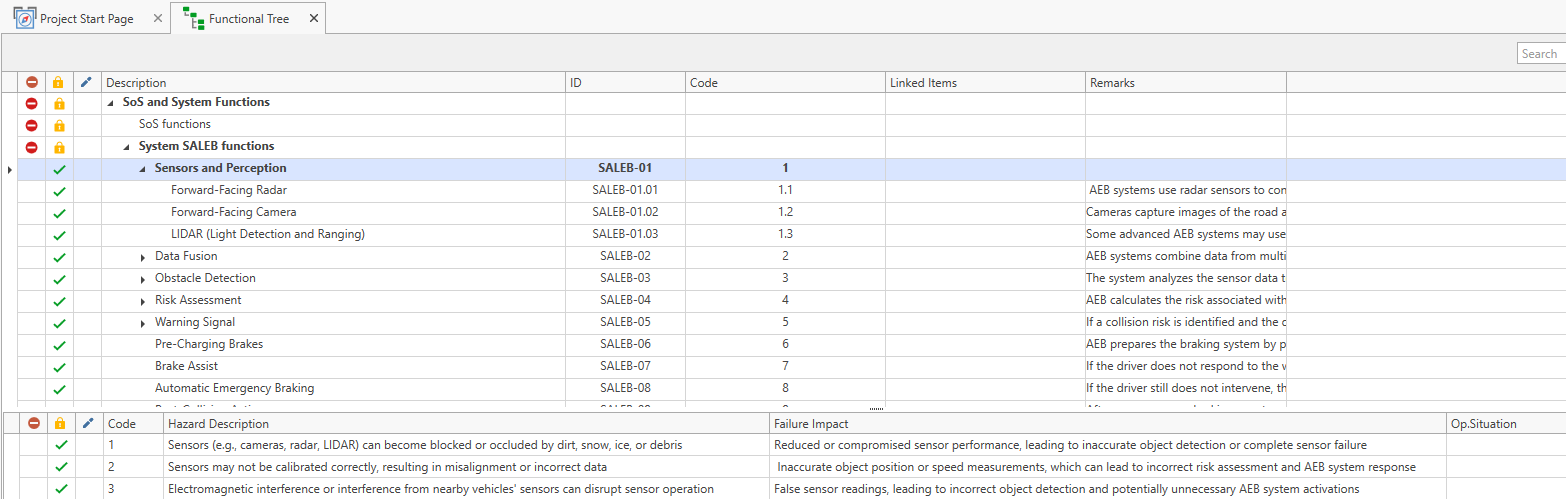

Functional Item Definition

The Item Definition will continue to evolve as we gain a deeper understanding of the design. We anticipate regular updates to the item definition as our knowledge grows

Schedule Safety Commander demo

HARA (Hazard Analysis, Risk Assessment and ASIL Determination)

Hazard Classification : classify identified hazards based on their potential impact, including harm to people, property, or the environment

Hazard Risk Assessment : assess the risk associated with each classified hazard. This involves evaluating the likelihood of the hazard occurring and the severity of its consequences

ASIL Determination : assign an Automotive Safety Integrity Level (ASIL) to each hazard based on its assessed risk. ASIL levels range from A (lowest) to D (highest)

Safety Goals Definition : establish safety goals for each identified hazard. Safety goals specify the required safety performance to mitigate or eliminate the associated risks

Functional Safety Concept : develop a functional safety concept that outlines how the vehicle or system will achieve the safety goals and mitigate the identified hazards

Technical Safety Concept : create a technical safety concept that describes the technical measures and strategies to achieve the safety goals and meet the ASIL requirements

Safety Requirements Specification : define safety requirements for the vehicle or system based on the technical safety concept. These requirements guide the design and implementation of safety-related functions

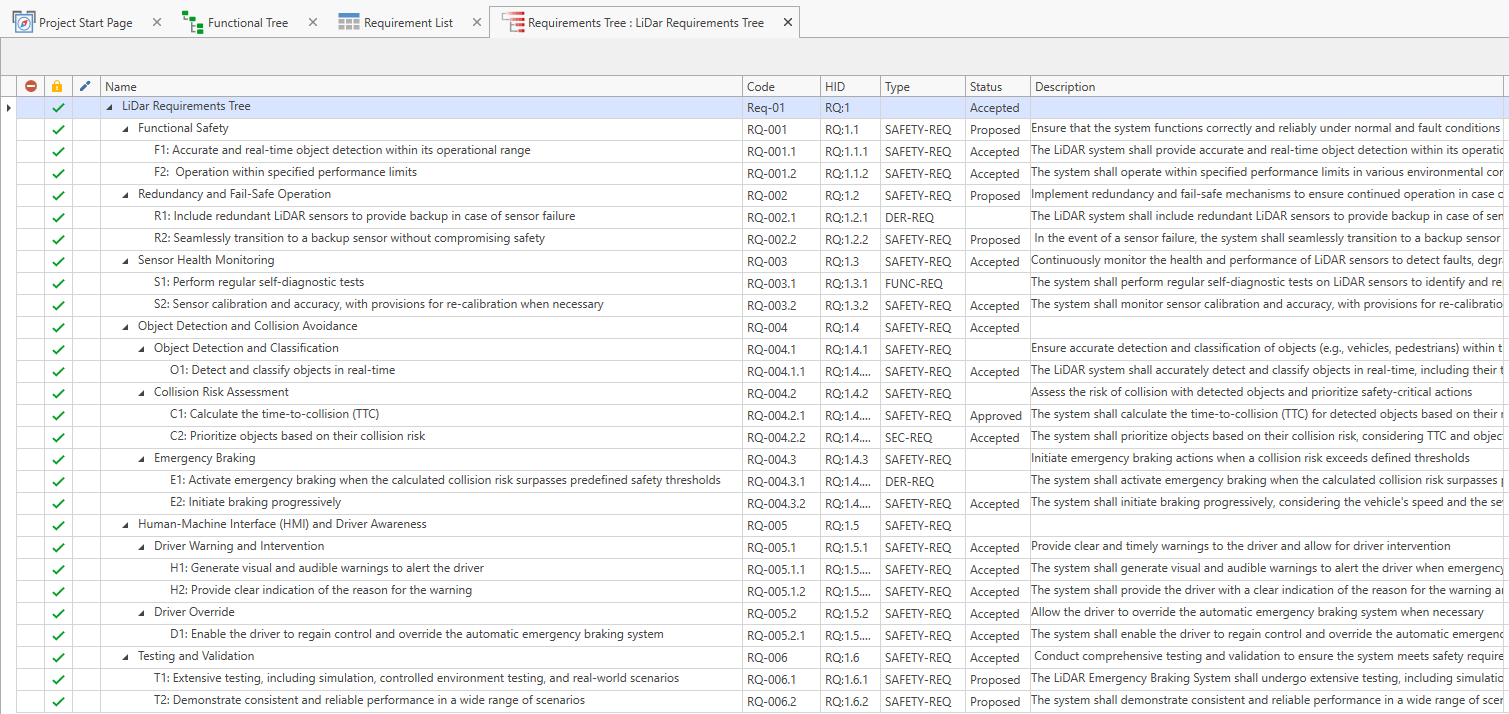

Requirement Management

Classification of Requirements : categorize requirements based on their relevance to functional safety. ISO 26262 distinguishes between safety requirements, which are critical for safety, and non-safety requirements, which are not directly safety-related

Requirements Traceability : establish and maintain traceability between safety requirements, derived requirements, and higher-level objectives. This ensures that all requirements are aligned with safety goals

Requirements Documentation : document all safety-related requirements comprehensively. The documentation should include clear descriptions, rationale, and any assumptions made during requirement development

Requirements Validation : verify that the safety requirements are consistent, complete, and feasible. This process includes reviews, inspections, and simulations to ensure that requirements are achievable

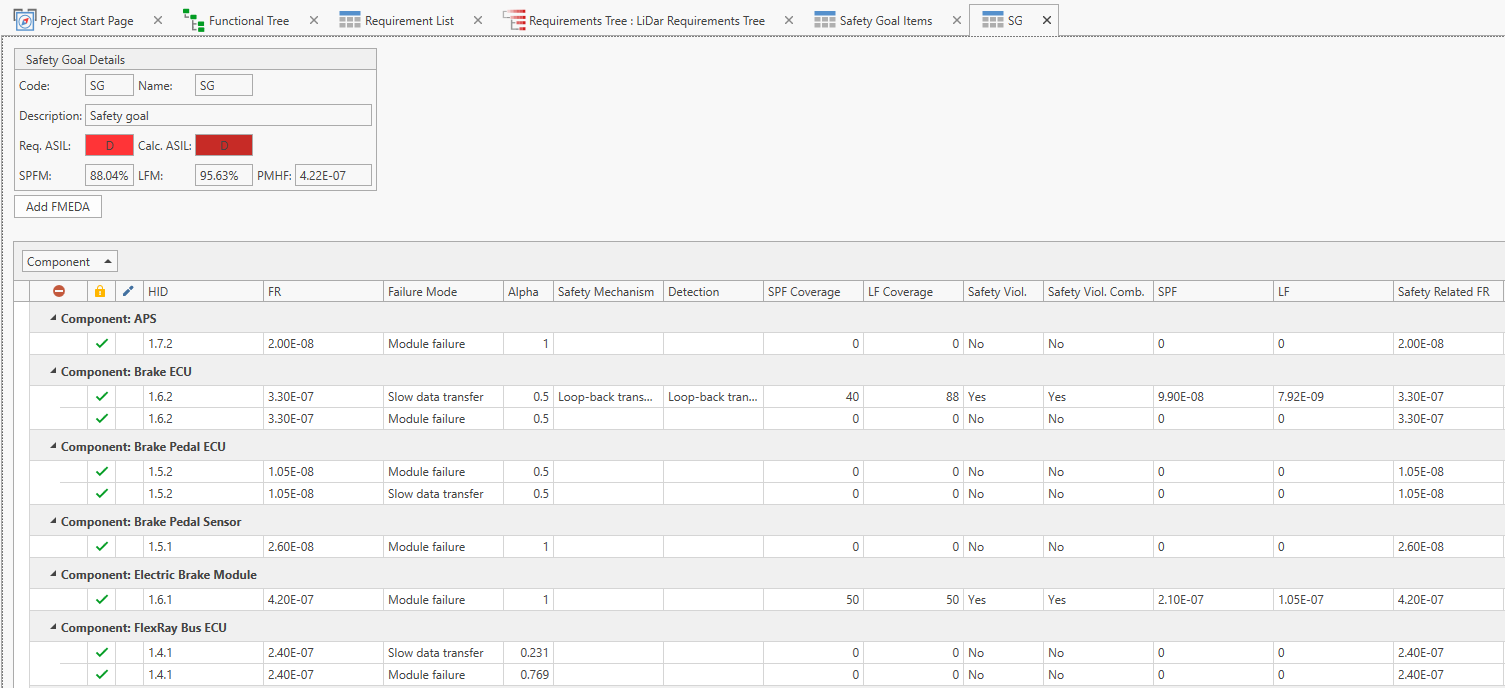

FMEDA (Failure Modes Effects and Diagnostic Analysis) Part 5 Hardware Metrics

FMEDA is a critical step in the safety assessment process of ISO 26262, as it helps identify potential failure modes, assess their impact on safety, and determine the effectiveness of diagnostic measures. This analysis contributes to the overall safety of automotive systems by reducing the risk of dangerous failures

Component Selection : identify and select the components (hardware, software, sensors, etc.) that are safety-critical and require FMEDA analysisFailure Modes Identification : for each selected component, identify potential failure modes. A failure mode is a specific way in which a component can fail

Failure Rate Assessment : determine the failure rates of the identified failure modes. This involves collecting data on failure rates from various sources, including field data, manufacturer data, and industry databases

Failure Mode Effects Analysis (FMEA) : analyze the effects of each failure mode on the safety functions and the overall system. Determine the severity of the effects, considering potential harm to people, property, or the environment

Diagnostic Coverage Assessment : assess the effectiveness of diagnostic mechanisms and safety measures in detecting or mitigating failure modes. Determine the diagnostic coverage of each safety mechanism

Single Point Failures Analysis (SPF) : identify and analyze single point failures within the system. Single point failures are failures that, if they occur, could lead to the loss of a safety function

Safe State Determination : determine the safe state or default behavior of the system or component in the event of a detected failure

Quantitative Analysis : quantify the risk associated with each failure mode by calculating the risk metrics, such as the Probability of Failure on Demand (PFD) and the Diagnostic Coverage (DC)

Safety Goal Compliance : verify that the failure modes, their effects, and the diagnostic coverage meet the safety goals defined for the system or component

Integration with Safety Requirements : Ensure that the results of the FMEDA analysis are integrated into the safety requirements and safety case for the system

Other ALD Software Tools

Safety Commander Enterprise Edition - Comprehensive software tool for Reliability and Maintainability Analysis and Prediction, Spare Parts Optimization, FMEA/FMECA, Testability, Fault Tree Analysis, Event Tree Analysis and Safety Assessment

D-LCC – Advanced tool for life cycle cost calculation, total ownership cost and sensitivity cost analysis